20 years Experience

Free Suggestion of product and free mold Design

Mold Size from 100kg to 45ton

More than 300 sets mold Capacity per year

Many Advance equipments and strong engineer team Guarantee high quality

2 years Warranty

Automotive injection mold

Advantages in processing and manufacturing

Provide OEM service for you in a fast, high-quality and mass manner

YIDA MOLD is looking forward to work with you together sincerely

About usAdvantage of YIDA mold

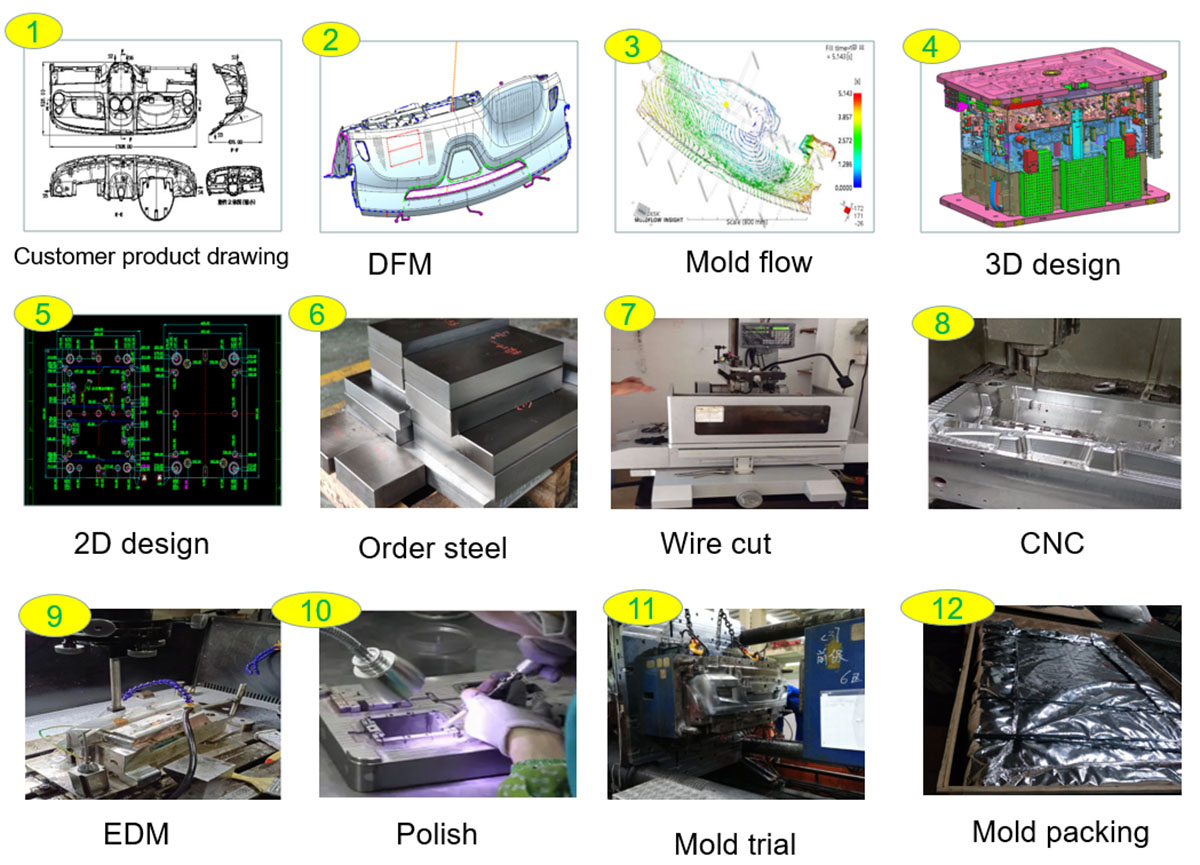

Appearance parts mold manufacturer.We have 25 professional designer with more than 15 years experience for product structure design and mold design.

.We design more than 500 sets molds for export market every year.

.Talent designer have more than 15 years of technology accumulation for part, mold and injection.

.We have fluent English technical team for good communication and fast response.

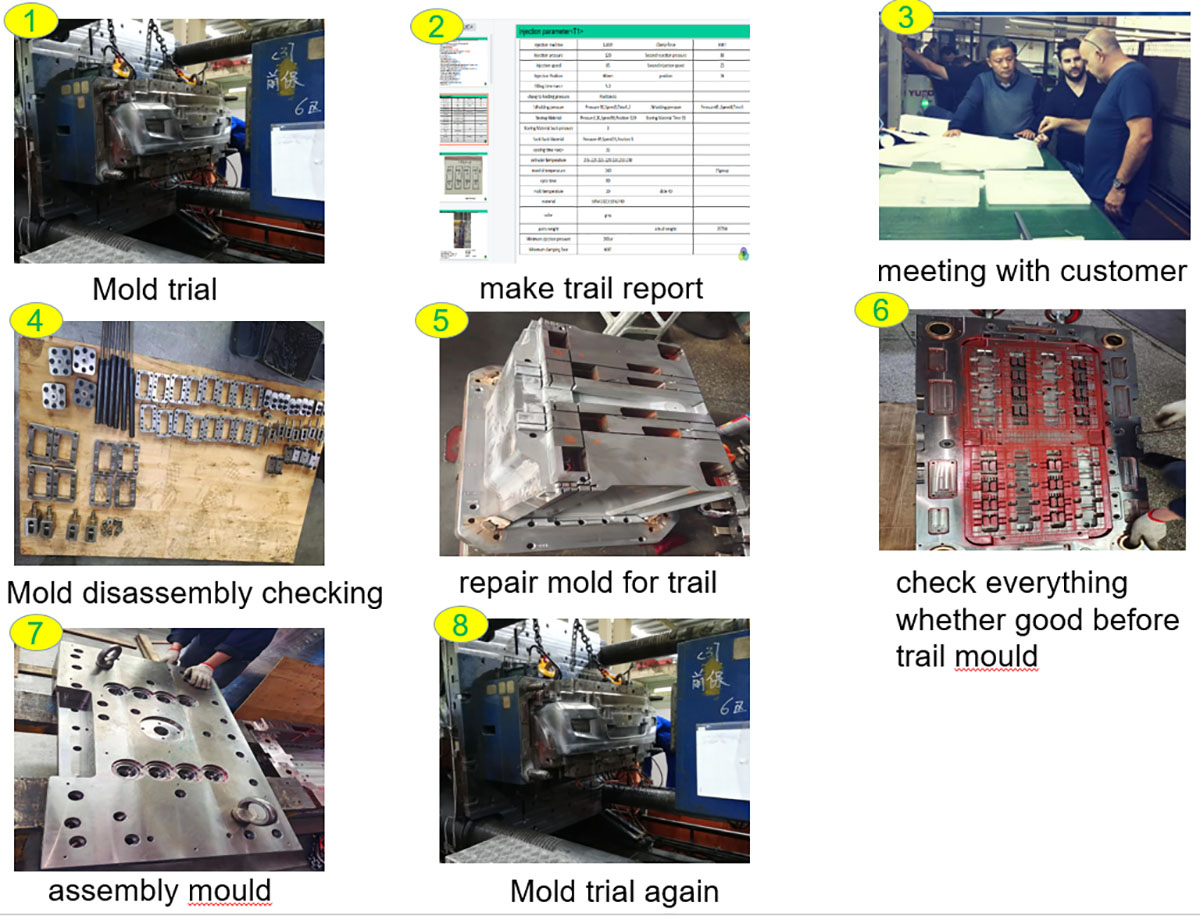

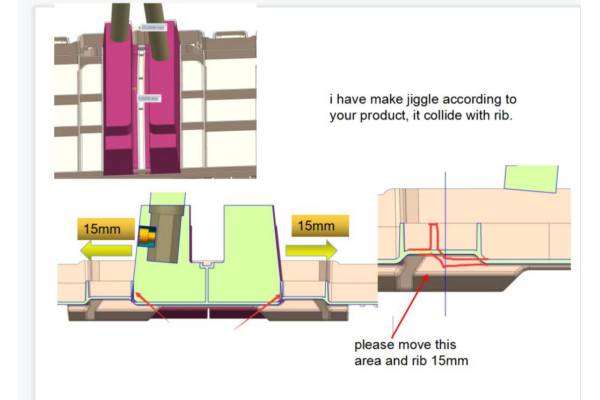

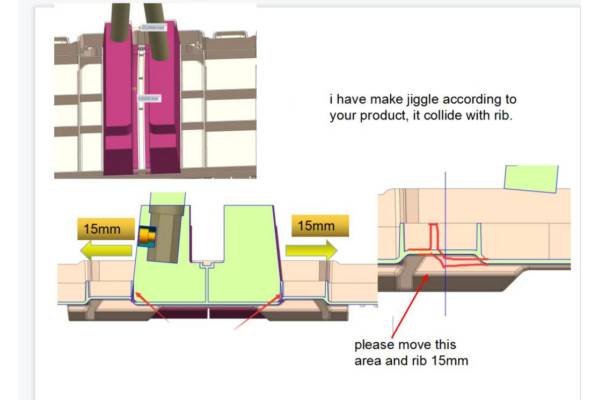

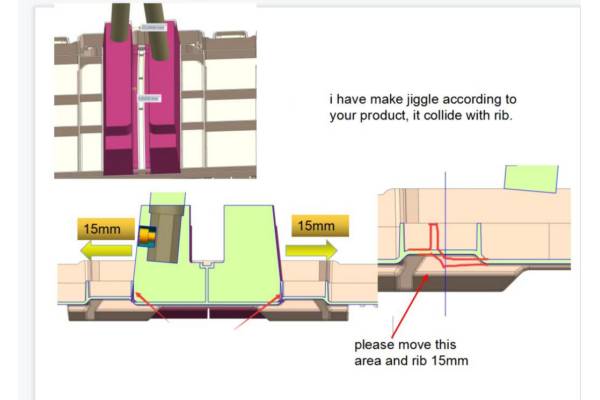

.We help customer make mold flow analysis by molding simulations. our technical team can optimize product design and mold design and will prevent many times modifications to the mold, reduce cost ,time and risk.

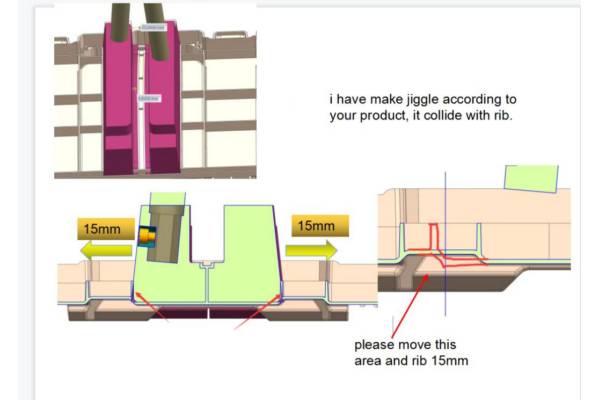

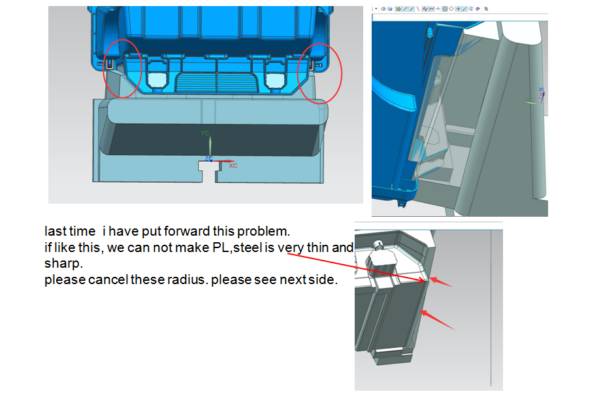

Product structure optimization 1

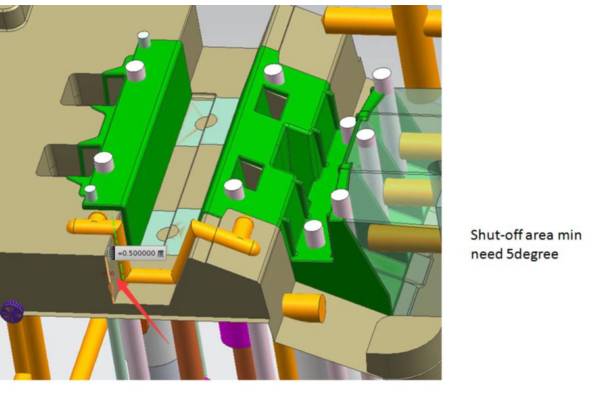

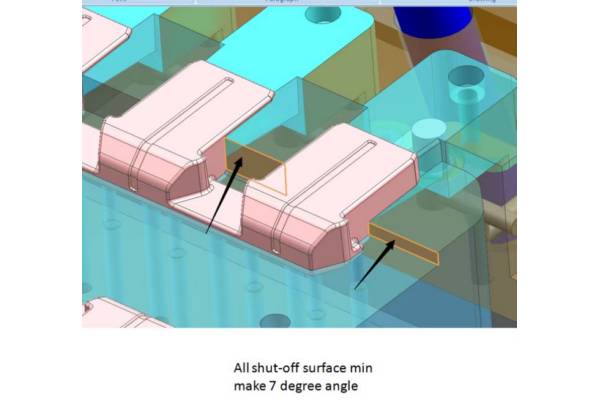

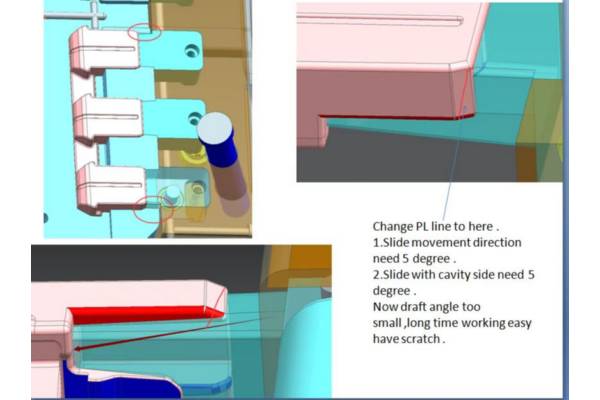

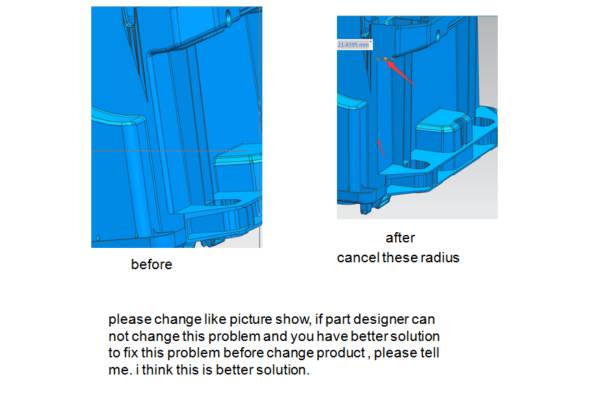

Product structure optimization 1 Product structure optimization 2

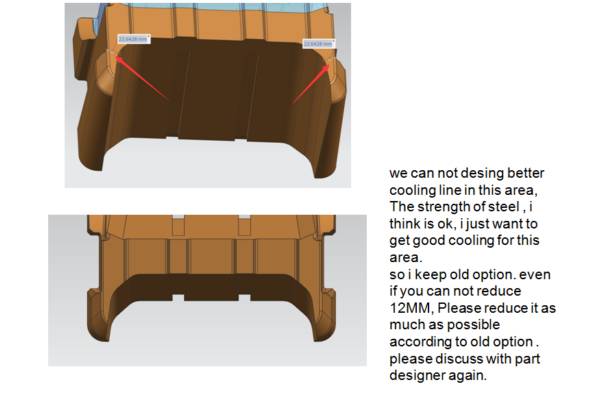

Product structure optimization 2 Product structure optimization 3

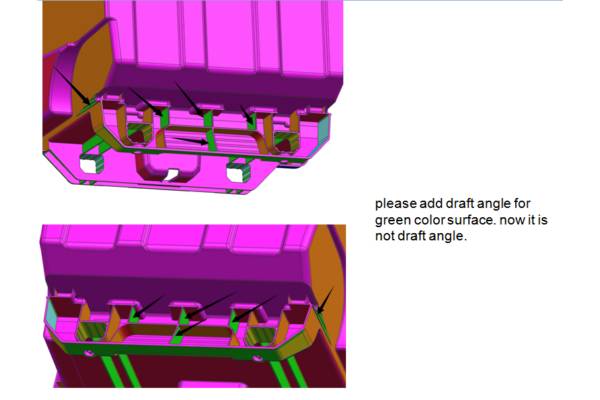

Product structure optimization 3 Product structure optimization 4

Product structure optimization 4 Product structure optimization 5

Product structure optimization 5 Product structure optimization 6

Product structure optimization 6 Product structure optimization 7

Product structure optimization 7 Product structure optimization 8

Product structure optimization 8 stack mould design 1

stack mould design 1 stack mould design

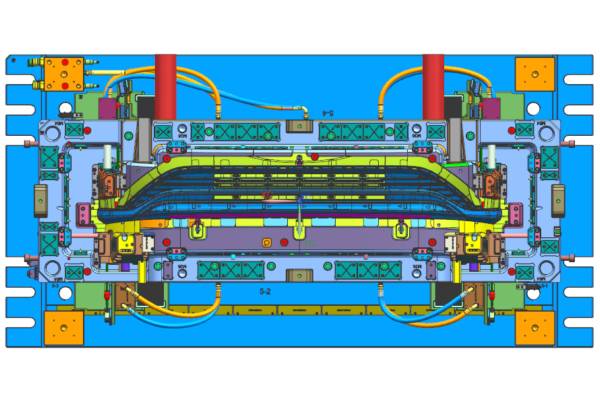

stack mould design Automotive bumper mould design

Automotive bumper mould design long core mould design

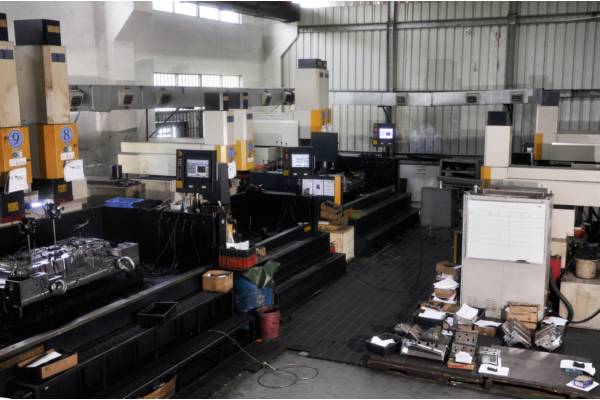

long core mould design.Advance Equipment

.Rich experience and responsible Manufacturing team.

.Quality Guarantee with GB/T 19001-2016/ISO 9001:2015

.Fast T1 time and delivery time

.3 years mold Warranty after sales

Assembly workshop

Assembly workshop Big CNC machine center 1

Big CNC machine center 1 Big CNC machine center 2

Big CNC machine center 2 CNC operation

CNC operation CNC processing 1

CNC processing 1 CNC processing 2

CNC processing 2 CNC processing 3

CNC processing 3 CNC processing

CNC processing EDM machine

EDM machine Fitting machine

Fitting machine High precision machining equipment

High precision machining equipment mold assembly workshop

mold assembly workshop mold assembly

mold assembly mold fitting

mold fitting.Injection molding with robot

.Professional skilled machine operator and injection technical team.

.More than 30 sets injection machine from 50Ton--3000 Ton

.Quality control from raw material inspection to mass production 100% part must past QC checking.

2400T injection machine

2400T injection machine Automation mass production maching

Automation mass production maching Injection workshop

Injection workshop Test injection maching 2800T

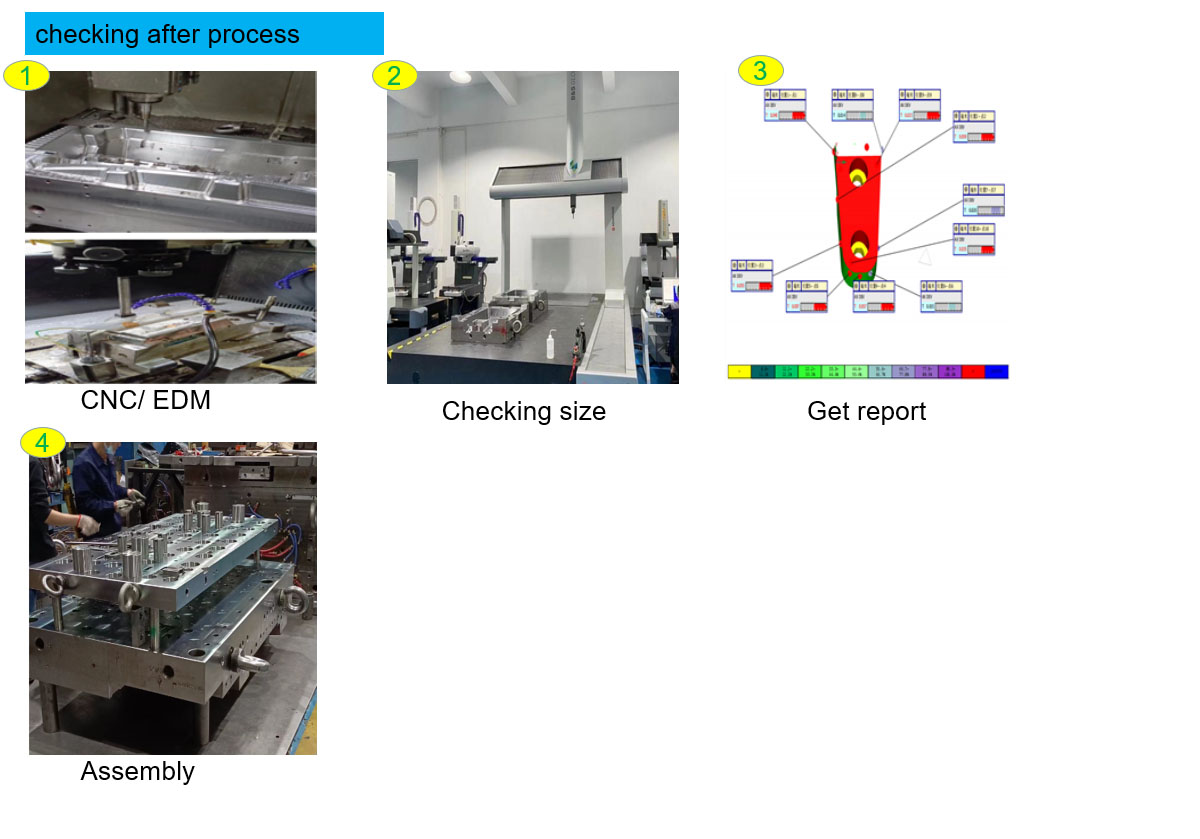

Test injection maching 2800T.Advanced testing equipment

.Strict inspection material steel and spare part quality, hardness inspection ,electrode inspection, insert inspection, use import steel (we can provide Certificate of origin) and famous brand spare parts.

.Good mold management system, provide weekly report for processing quality checking and time table

checking mold

checking mold CNC Coordinate Measuring Machine 1

CNC Coordinate Measuring Machine 1 CNC Coordinate Measuring Machine 2

CNC Coordinate Measuring Machine 2 CNC Coordinate Measuring Machine 3

CNC Coordinate Measuring Machine 3 hardness tester

hardness tester QC department

QC department Quality checking

Quality checkingCooperative client

COOPERATIVE PARTNER

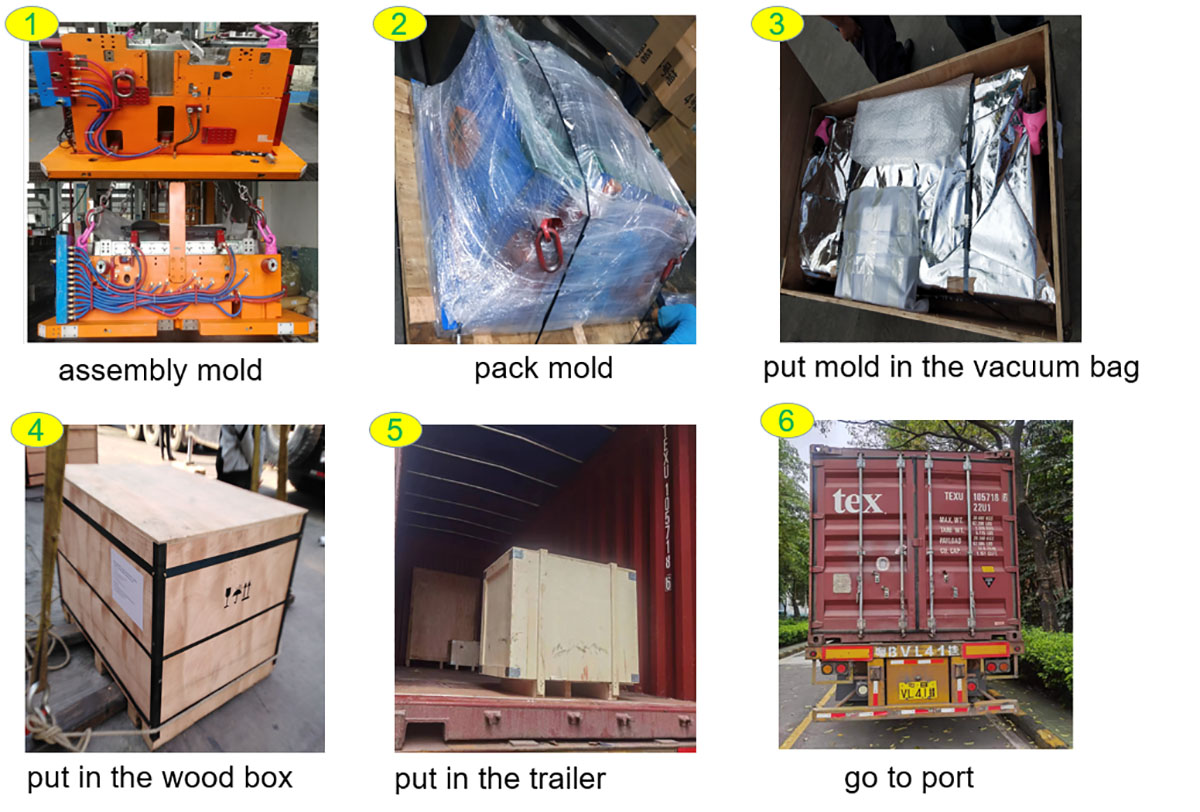

Work together with customers from part developing ,mold Design, Prototypemold process, mold test, modify still mass production.

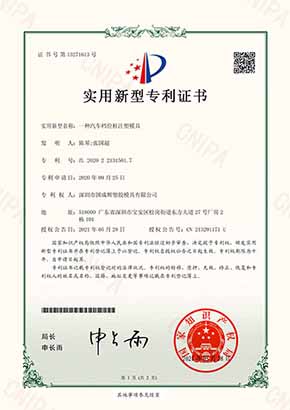

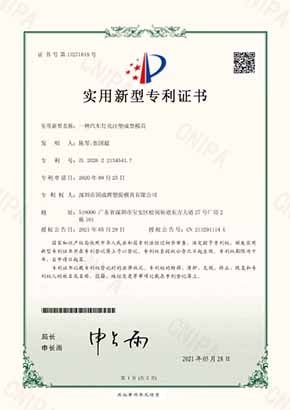

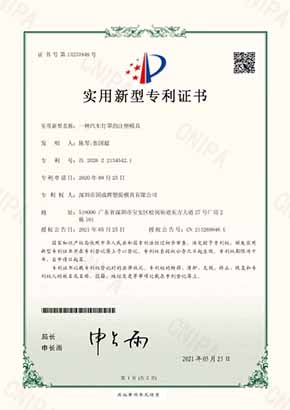

Factory certification patent

Custom process